“Record Breaking Snow in the Maple Forest”

Hello Everyone:

After the snowiest winter in Wisconsin history we are happy to be making our maple syrup. The first significant sap run of 2019 began on March 21 after a quick temperature rise to 51°. We always begin by tapping a few trees in mid to late February just so we can watch for any sap production. Once we know the temperature will move up to the mid-forties we make sure to have at least 150 to 180 trees ready. Currently we have 200 trees tapped, and we will likely finish with around 220 trees before the season ends. By now maple syrup season is coming to an end for states such as Ohio, Indiana, and Illinois, while it is in full swing in Wisconsin.

The 2018 season lasted about six weeks, but it was quite cold at times, with up to five to seven days below freezing in a row. Most of the sap collected last year came in late March and early April, resulting in total production of 32 gallons.

As many of you know, our small operation is all done the old-fashioned, traditional way. Collections are done by tapping trees with drills and metal spiles. Two- to three-gallon tapered aluminum pails are then hung below the spiles. The sap is collected by hand and all of the evaporation is accomplished over wood heat.

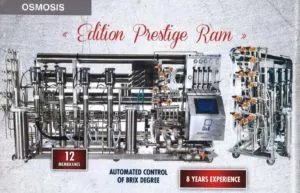

Today most commercial operations include vacuum pumps that pull sap out of trees, and plastic tubes and lines that funnel sap into storage tanks and reverse osmosis units. These units essentially separate as much as 40 percent of the water from sap by pushing it through a rubber membrane. This reduces the amount of sap that is evaporated and can reduce the cooking time. Of course, this isn’t the “old-fashioned” way.

Reverse Osmosis

Our sap is gravity fed from a stainless steel storage unit into the evaporator. A float keeps the sap feed equal to the liquid evaporated. About 40 gallons of sap must be evaporated to yield 1 gallon of pure maple syrup. Cooking time is slower; however, we still think it’s worthwhile. There’s just something special about tradition. We think the syrup ends up with a rich and superior flavor, making it unique.

This old style method of collecting has more hands-on work in the process. Everyone that is out collecting the sap buckets will have a surprise at each tree, as some may be overflowing and others may have produced only a small amount.

We still have lots of snow!

We empty the smaller sap buckets into 5 gallon pails and carry them to a 100 gallon tank, which is on a small trailer pulled by a four wheeler. We have various trails that run through the tapping areas. In 2018 we added more trails so we could start tapping new trees, giving a rest to some of the trees that have been in production for almost 20 years.

Once we have 150 to 200 gallons of sap we can fire up the evaporator and start cooking. The majority of this work is done on the weekends. With a heavy sap run, we can collect anywhere from 300 to 400 gallons; cooking is done daily to keep up.

Evaporator

A good 10-hour day of evaporation allows us to boil about 200 to 225 gallons of sap, which yields 5 to 6 gallons of ‘near syrup’. This is very close to being perfect, but we typically store ‘near syrup’ until we have 10 to 15 gallons. This batch will then be completed by using a small gas heating unit where we are able to precisely control the heat. This unit has a stainless steel tank that can hold 15 gallons of ‘near syrup’. The last of the water is boiled off, filtered, and now the syrup is ready to be bottled. It’s a fun process that starts with gin-clear sap and finishes with a rich golden brown syrup at day’s end.

This is the current model we use.

Home-made syrup, like good bottled wine, has its own unique flavor profile. This may depend on things like the soil type, tree genetics, and the length of sap evaporation time. The profiles aren’t nearly as distinct and varied as wine, but I read a publication some years ago that identified around 30 different types of syrup. Many of our friends think our syrup has a lush vanilla flavor.

Today there is a strong emphasis on syrup grading, which runs from a pale amber to deep golden brown. Most of the lighter colored syrup is produced early in the season and the darkest syrup is at the end of the season. The darker color is due to the higher nitrates and minerals in the sap. We do not grade our syrup, since we do not have it for commercial sale. Honestly, I enjoy the taste of all our maple syrup.

In this issue I have included pictures of some of the sophisticated evaporators on the market. As you can see they can be very complex. Ours is flat with three channels that move the cold sap through the start and hot, darker ‘near syrup’ at the draw off. It’s pretty simple and yields delicious syrup. It also costs a lot less.

There are several ways to enjoy this delectable treat, but one of the best ways is to drizzle it over rich and creamy vanilla ice cream. If you really want an extra pop of flavor, toss in some pecans roasted with a coating of maple syrup and a pinch of sea salt.

My personal favorite is hot fluffy pancakes, some smoky bacon with a drizzle of our maple syrup and a side of eggs over easy. You probably shouldn’t indulge in this breakfast every day, but it sure is a great way to kick off a weekend of making maple syrup.

I’ll try to get a second edition out at the end of the season. We did bottle 18 gallons of syrup on Sunday with the help of our family and friends. If you have time to visit, please give us a call, so we can let you know when the sap is running.

Plowed snow around the sap house.

Grandson Ted with the equipment.

Plowing was required to open the trails.

Todd and Ted tapping. Snowshoes and

a pull-behind sled were a must this year.

All the trees need to have the snow

shoveled from the base.

Todd and granddaughter Jennie

collecting sap.

Evaporator is hard at work.

Bottling finished syrup.

Mary Lee proudly celebrating

our finished product.

Here is a family favorite recipe at our home. We hope you enjoy it as much as we have over the years!

Ed and Mary Lee